Home > Log Home- Compatibility

Compatibility:

CPES™ and Layup and Laminating™ Epoxy Resin Used with Other Wood Treatment Products

We get many questions about the compatibility of CPES and other products, primarily from log home owners although what we have to say applies to everyone. The questions tend to fall into two main categories: preventing rot from spreading to good wood, and the application of stains or insecticides/herbicides before treating good wood with CPES. Our answer depends largely on the agent that is used to get the stain or insecticide into the wood.

If the wood is soft, punky or rotten, what we have to say below has less importance. Clearly, whatever was put on or in the wood (if anything) didn’t work. It’s bad wood and it needs to be treated with CPES to restore it to useful strength. We believe that nothing should be put on bad wood before the CPES. After the treatment with CPES and, if necessary, Layup & Laminating™ Epoxy Resin, then you can put just about anything you want on the wood.

On good wood the application of CPES, especially in cracks, crevices, knots and log end-grain can go a long way toward retarding the access of moisture and the development of rot and bacterial decay. Any freshly applied oil-based coatings, which is the majority of your log treatment products, will retard the penetration of CPES. Over time they oxidize away and the wood is essentially bare again, which is why they must be reapplied at fairly frequent intervals.

Water-based coatings will not interfere with the penetration of CPES, once the wood has dried. This category includes disodium octaborate tetrahydrate dissolved in water, which can be useful in retarding rot - as long as you remember that the borate will be leached away by water and that some bacteria tolerate the borates fairly well. There are some biocides that are applied in a water base and they too will have no effect on the penetration of CPES, once the wood has dried.

CPES applied to a sound wood surface can modify the appearance of subsequently applied wood surfacing products, unless the surfacing product is highly pigmented. We would suggest you test. A somewhat mottled look may be the result. CPES itself is a highly effective wood surface treatment product, giving the wood about the same coloration as a coat of clear varnish. However, the variety and condition of wood is so variable that we recommend that you test a patch first to be sure you’re going to like what you see. All epoxies are good UV protectors, until the UV light breaks down the epoxy molecule. Consequently, like any wood surfacing product, they must be reapplied at intervals. On good wood surfaces you can expect about 300 square foot coverage per gallon of CPES.

Cracks, crevices and knots primed with CPES and then filled with Fill-It or a Layup & Laminating Epoxy Resin/sawdust mixture will absorb very little of any surface coating. Either the L&L/sawdust or the Fill-It Epoxy Filler can be toned to any shade of brown by using our Epoxy Coloring Agent. We suggest you put down a stain sample and match the color of the stained wood. We do not recommend that cracks be filled with a standard putty or caulking compound. They almost always leak water, and then you have ideal conditions for rot and bacterial decay. Use a hard epoxy fill, primed with CPES.

There is at least one product out there that mixes disodium octaborate tetrahydrate with a glycol, claiming penetration and protection of the wood. There are others who use antifreeze (also a glycol) to preserve wood. We decided to test a glycol product and see exactly what it did in a soft wood and whether CPES would penetrate through or around it.

We used the same wood (soft balsa) and the same procedures that we used in testing CPES against competitive products. Click here for our Testing Section if you want to see these procedures and results.

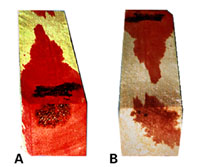

The pictures (right) tell the story. The first picture (A) shows the balsa piece end close to the product introduction point and the second picture (B) the end away from the introduction point. We would like to emphasize that the broad spread of red glycol on the outside of the wood is a surface spread, i.e., it leaked out the end and then spread. A cut into the log shows a red-spotted “chicken pox” cross-section, showing that the glycol follows the channels and does not spread so readily inside the wood.

The pictures (right) tell the story. The first picture (A) shows the balsa piece end close to the product introduction point and the second picture (B) the end away from the introduction point. We would like to emphasize that the broad spread of red glycol on the outside of the wood is a surface spread, i.e., it leaked out the end and then spread. A cut into the log shows a red-spotted “chicken pox” cross-section, showing that the glycol follows the channels and does not spread so readily inside the wood.

The dark areas in the picture are dyed CPES which was applied over the glycol after it was dry to the touch. You can see that CPES penetrated through the glycol (large dark area on near-end and small dark spots on far-end photo), although at a reduced rate compared to penetration in untreated wood. We estimate that the glycol cut the amount of CPES penetration by about 50%.

So what about glycols? We really don’t see the point. Glycols, like borates, are dissolved out of the wood by water over time. Furthermore, unless you use the poisonous ethylene glycol in antifreeze, the bacteria and other very small life forms will eat it. If you want the borates in the wood, just put them in with water.

And this is the whole advantage of using an epoxy. The epoxy in our CPES shows a definite preference for deteriorated wood, which is of course exactly what you want. It saturates and bonds to the bad wood fibers, hardens, and makes the wood unpalatable for fungi and bacteria. Where the rot fungi go, so goes the CPES.