Contrary to popular belief, the weather is very extreme in Hawaii. Yes, the average annual temperature is 80+ degrees and there are usually at least 200+ days of sunny weather. This is great for sun-worshipers but really bad for houses here in Hawaii. Throw in the salt laden ocean air, trade-winds, rainy season storm gusts approaching 50 MPH, sheets of vertical and horizontal rain hammering the sides of our house from the East and South, and you have wood rot and insect infestation problems up the yin-yang no matter what type of wood is used in the construction of your house. It’s not a matter of if but a matter of when you will have these problems.

To make matters worse, a miss-aimed sprinkler head that has been soaking the underside of the living room windowsill (eastern exposure) and damaged the wood sill where 50% of the sill had wood rot running horizontally along the leading edge. Fortunately the wood supporting the casement-window bracket hardware was still solid but if not treated soon the wet wood rot would spread to the good wood and adversely affect the operation of the window.

The first step I took was to examine the damage closely and to use an awl to poke and assess whether to replace or repair the damage. After a thorough inspection I determined that there was a lot of wet wood rot that extended at least 2 to 3 inches below the windowsill surface. This made it a perfect candidate for repairing the damage using The Rot Doctor’s CPES™* solution. I read the instructions and articles on outdoor wood repairs on their website and the results they achieved using the syringe injection method gave me the confidence to tackle this repair.

The tools and parts used for this repair are the following:

- 2 quart kit of CPES™*

- Cordless drill with 3/8″ bit

- Medicine syringe with plastic tubing

- Epoxy Resin

- Sandpaper

- Hollowed out aluminum soda can for 1:1 mixing of the CPES™* epoxies

- Wood stick for mixing

I was able to see for myself how the CPES™* really penetrates deep down into the wood fibers and how effective it is in both hardening and strengthening all of the wood that it bonds with. The job took about a week due to all of the rain we have been having here lately. I could have completed the job in 2–3 days if not for the rain. I was also faced with the challenge of injecting the CPES™* into wet wood as I was unable to completely dry out all of the wood fibers. Here is a brief description of the repair procedure:

1) Assessed damage by marking all soft areas of the rotted window frame. Took note of the “good” wood and marked off the soft areas. The unseen wood rot is pretty pervasive on this window sill and the good wood is closest to the inside of the house. The outer 2 inches is clearly soft and the layers of paint have been holding the moisture captive to the wood and had been hiding the damage.

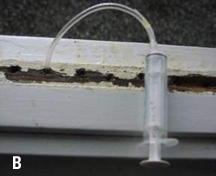

2) I determined that the best way to get the CPES™* into the wood would be by drilling 1/2 inch diameter vertical holes spaced every 3/4 of an inch down to a depth of about 2 1/2 inches. Alternative of cutting and removing sill would be much more work and aggravation. The CPES™* would be injected using a syringe.

3) Mixed the CPES* as directed using a 1:1 ratio. Used a hollowed out aluminum soda can and used disposable medicine syringes which worked pretty well.

4) I started to inject the CPES™* into the holes and guessed that I would use 18 to 32 ounces max for this repair. Boy was I off! It used all 64 ounces of the CPES™* solution. It literally soaked up the CPES™* like a sponge. I was happy to see this occur as I wanted to make sure that all of the wood fibers were saturated with the epoxy. I also used a hair dryer to hasten the drying and setup time in between injections.

5) Since we were getting hammered with rain, I covered the windowsill with Aluminum Foil and duct tape to keep the water out of the window sill.

6) After a day’s worth of drying (24 hours) I could see that the windowsill got noticeably harder due to the CPES™* drying and setting. It had soaked and permeated into every molecule of that window sill.

7) After 2 days of drying, I used a chisel to cut a 1.25″ wide channel into the window sill so that the epoxy filler would have a better chance of bonding to the dried CPES™* and wood fibers. More epoxy would be better due to all of the wet wood in the edge of the windowsill.

8) I used Epoxy Resin as the final filler. This took about an hour to setup and about 24 hours to fully dry.

9) After 36 hours of drying, the repair has been completed and the soft wood is gone. The entire window sill has been saved and is now rock solid and ready for an oil based primer and marine grade oil based top coat paint.

Update: 5 days after completing the repair. The windowsill is rock-hard with no weak or soft areas. I am very happy with the results and extremely impressed with the CPES™* product. The repair cost in materials alone was about $75 dollars total. In addition, I also had the satisfaction of knowing that the repair was done properly from start to finish. BTW, I received estimates of between $300 and $500 to repair/replace the windowsill from 3rd party contractors immediately after closing on the house in July.

I will not repair any wood rot in my house without using CPES™*. Consider me one of the newest converts and believers in the Rot Doctor.

Go back to Using our Epoxies

* These products are unavailable, we are selling comparable products that will perform these same tasks. Feel free to contact us if you need assistance with which products to use.